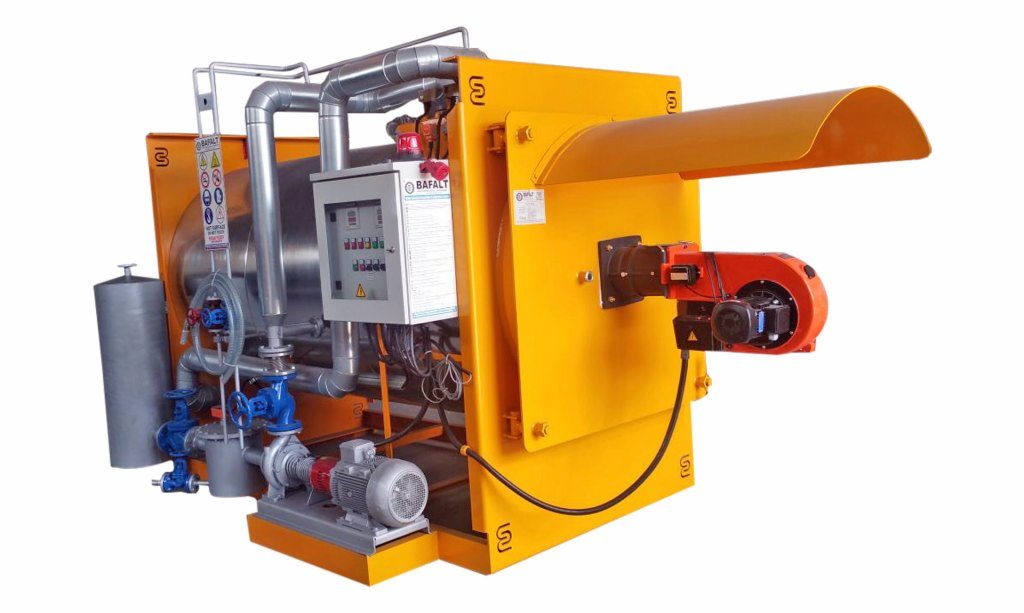

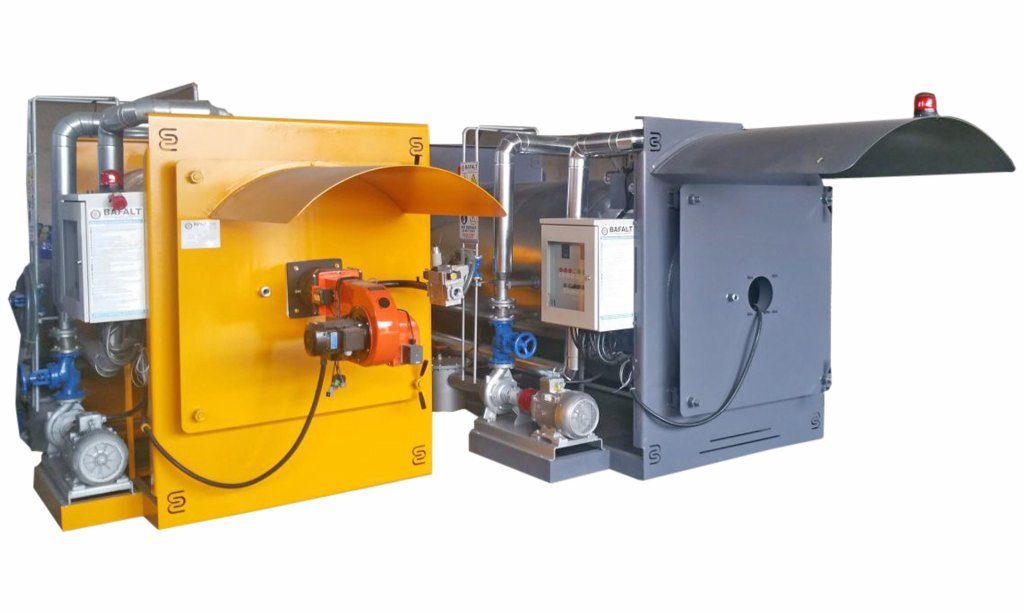

Hot Oil Generator

Our hot oil generators with BAFALT brand; it is designed to be used with both liquid and gaseous fuels, taking into consideration the characteristics of gas fuels such as natural gas and LPG, liquid fuels such as Motorine, Fuel Oil, three-pass, turbulent, full Cylindrical.

Our hot oil generators;

- manufactured a capacity of 500,000, 1,000,000, 1,500,000, 2,000,000, 3,000,000 kcal / h standard production.

- Our products have TSEK and CE (B + F) certificates.

- The operating temperature is between -10 oC/ 300 oC.

- Compact design (can fit into the20 ‘ container) for easy transport and installation.

- Safety, flow, temperature and pressure are secured with 8 security sensors used at the oil inlet and outlet.

- Thermal oil inlet-outlet temperature difference is projected in computer environment after calculations are made taking into consideration many parameters.

- BAFALT has high efficiency because of its three-pass oil turbulator and turbulator. The applied construction criteria and the width of the combustion chamber were reduced to the maximum level in the synthetic oil without thermal cracking, the thermal inertia of the hot oil generator was minimized and the combustion and heat transfer efficiency were maximized.

- In the BKYK hot oil boilers that we produce as BAFALT ASPHALT MACHINE, the boiler sheet conforming to EN 10028 norm is used at the body. Hot oil circulation pipes are manufactured from PGH235 TC1 steel drawn pipe.

- The hot oil generator outer shell is insulated as galvanized, aluminum or stainless steel on suitable rock wool. In order to protect the affected parts of the flame, a suitable form of refractory material is placed in the boiler.

- Bafalt brand hot oil generator has 8 safety valves which aim to reduce the risk to minimum level by integrating the necessary control and automation equipments (temperature, pressure, flow control) in the system against any kind of malfunction.

ABOUT HOT OIL BOILERS (GENERATORS)

Today, many branches of the industry require high temperature and heat transfer systems at these temperatures. Boiling water and steam systems can respond to these needs by ascending certain pressure values. However, the pressure values required to reach high temperatures bring boiling water and steam systems to a disadvantageous position in terms of cost, efficiency and safety. Heat production and transfer at high temperatures can be achieved efficiently and safely with hot oil systems.

Hot oil systems are systems that are used to satisfy the high temperature fluid requirements of industrial plants that other alternative fluids can not reach at low pressure.

In hot oil systems, various thermal oils are used which can be heated up to 300-320ºC at atmospheric pressure without losing their properties. Due to the properties of the fluid used in the system, there is no reduction of the system such as corrosion and lime bonding in installations and devices.

Locations of Use of Hot Oil Generator;

Textile, Dyehouse, Paper – Cardboard, Petroleum Industry,

Rubber, Leather Industry, Chemical Industry, Oil Industry,

Asphalt, Bitumen, Detergent industry, Varnish, Paint manufacturing, Cannery,

Timber, Parquet, Bottling, Paint Ovens, Sludge Drying, Recycling Industry, Jam Industry, Dried Fruit Industry, Turkish Delight Manufacturing Industry

BAFALT HOT OIL GENERATORS

Reasons for Preference of Hot Oil Systems in Industrial Use;

Better temperature control:The temperature control in hot oil systems can be done much more perfectly and effectively with automatic control valves. This is a great help in providing a standard quality in the manufactured product.

Low operating and maintenance costs: Considering operating costs, system efficiency, staffing, water, maintenance, repair and spare parts costs, the operating and maintenance costs of hot oil systems are much lower than steam systems.

The system is safer because of the low pressure:Compared to the steam system, the hot oil generators are operated at low pressure and open to the atmosphere through expansion tanks. The pressure in the system is limited to the pressure required to overcome the boiler and pipe losses in the hot oil circulation pumps. The use of hot oil boilers with low pressure and safety systems requires fewer qualified employee than steam systems.

Long-life use of the system:Hot oil systems can be used in enterprises without needing to be renewed for a long time if the necessary maintenance, periodic inspection and cleaning are done completely.

High yield:The hot oil generators are less efficient than the steam boiler efficiency due to the high flue gas outlet temperature. When considered as a system, the hot oil system is more efficient because there are no condensate losses, bluff losses, flash steam losses and water losses in the steam system.

Another feature of hot oil systems is that hot steam exchangers can also be used to satisfy steam needs. Hot oil / steam exchangers can be easily integrated into the system since they do not require additional and space-saving equipment such as chimneys, fuel tanks.

Higher flue gas values that appear to be disadvantageous in hot oil systems can be used to improve boiler efficiency or to satisfy the operator’s hot water and air needs through heat recovery systems such as an economiser or air heater to be placed at the exit of the chimney.